UBC’s award-winning Third Quadrant Design – a team of more than 60 students in engineering, architecture, business, and arts – is about to start construction of a new student space on campus that redefines sustainable design.

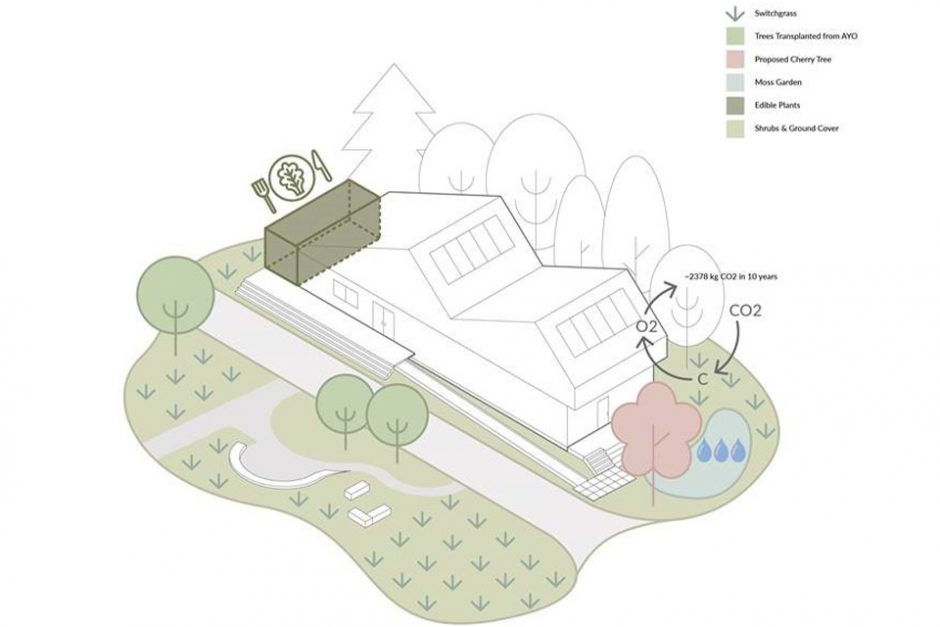

The 247-square-metre building, officially known as the Third Space Commons, will serve as a collaborative working space and living laboratory for students, industry partners and researchers to investigate zero emission, regenerative and climate-resilient design.

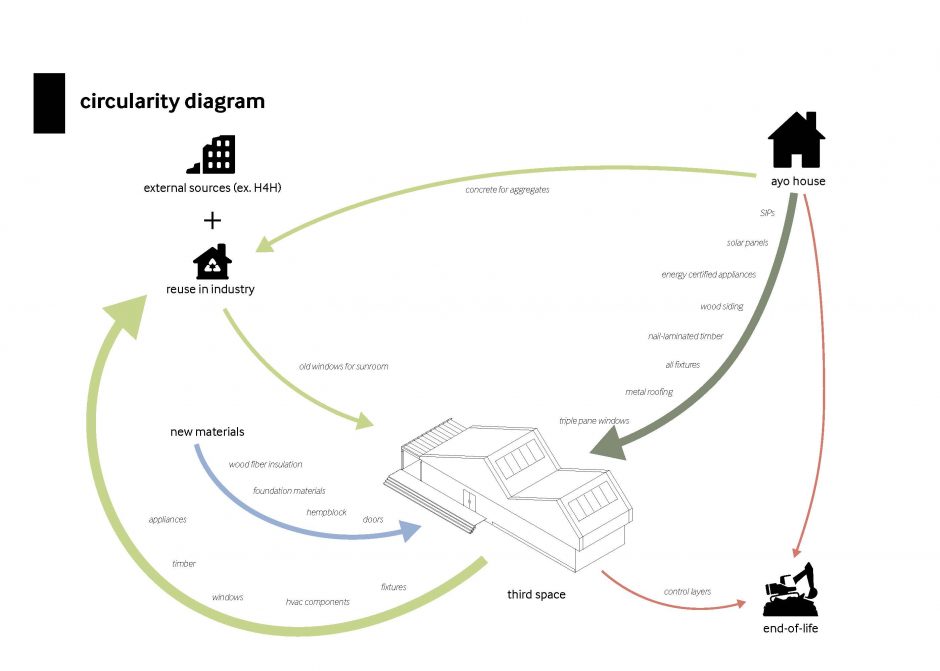

As a result of the team’s innovative choices in design, building materials and construction processes, Third Space Commons will potentially sequester more carbon than it emits over its life cycle. This goes far beyond conventional definitions of net zero, which tend to focus solely on a building’s energy efficiency.

Faculty advisor Dr. Adam Rysanek, Assistant Professor in UBC’s School of Architecture and Landscape Architecture, sees the students’ work as ground-breaking: “The idea of net-zero embodied carbon – to actually build a building that’s truly net zero – is something that has not yet been done by professionals to say nothing of students. That’s why this building will be hugely important for advancing the discussion and implementation of net zero in this province.”

How low carbon can a building be?

“Buildings are inherently carbon intensive,” explains Milan Jaan, the team’s Design Manager. “Even the simple act of excavation releases carbon stored in the ground into the atmosphere. The question we’re looking to answer is just how low carbon a building can be without compromising on architectural form, engineering function and human interactions with and within the space.”

Answering this question requires taking a holistic view. Katie Theall, an architecture student and the project’s Co-Captain and Architectural Lead, notes that policies and building codes focus on operational carbon, which is the energy used to maintain a building’s energy requirements for heating, cooling, lighting and power.

“But when you look at the full life cycle – including the embodied carbon of materials, operational carbon and what happens at the building’s end of life – it is interesting to discover that in BC, in particular, embodied carbon has a much greater impact than operational carbon,” she says. “Our project focuses on total carbon, which is a more holistic approach.”

In practical terms, this means carefully analyzing the life-cycle carbon impact of every single item used in the building’s design and operation, as well as associated construction practices, to choose low-carbon or net-zero-carbon materials and processes.

Challenging trends

The students are challenging prevailing industry trends that favour some products over others, says Alicia Hobmaier, a fourth-year integrated engineering student and the project’s Co-Captain and Engineering Co-Lead. She cites the example of heat pumps, which are a popular design choice to help buildings achieve operational energy-efficiency standards. “While they offer lower carbon emissions than other heating and cooling mechanisms, their manufacturing processes and the refrigerant they use means they have higher embodied carbon.”

Trying to reduce carbon emissions to net zero is informing decisions being made for all other aspects of the building – such as choosing light wood framing rather than engineered wood, which incorporates fossil-fuel-derived glues.

Agustina Flores Pitton, a third-year civil engineering student and the project’s Co-Captain and Engineering Co-Lead, says the team’s focus on regenerative design meant they also had to explore alternatives to concrete.

“Because of its high embodied carbon, using concrete in the foundation would completely offset any mitigating measures we could take above ground,” she says. “We’ve chosen a helical pile foundation instead. Steel helical piles have lower embodied carbon than a concrete strip foundation, both in materiality and construction, and they can be reused at the end of the building’s life.”

One particularly innovative design choice is the use of hempcrete, a composite material made of hemp and lime. “Some residential buildings have used hempcrete, but we think this might be the first institutional project to do so,” says Theall. “In typical high-performance buildings, you use insulation and membranes to create a thick envelope, but these materials tend to have high embodied carbon values. Hempcrete actually sequesters carbon as it hardens. So both during the growing phase of hemp and as it is used in the building, it captures carbon to have a positive environmental impact.”

Two-year challenge

Formed in 2019 by three female engineering students, the student design team is a two-time winner of the U.S. Department of Energy’s Solar Decathlon Design Challenge: in 2019/2020 for the design of a single-family home and in 2020/2021 for its design of a five-storey mixed-use retrofit building.

This year’s team is entering the Build Challenge, a two-year design-build competition. Based on their initial designs for the Third Space Commons at the UBC Vancouver campus, the team received US$50,000 in prize money and the approval to enter the build phase of the competition where they will be competing against 36 other institutions from 10 countries.

The group received their development permit at the end of June. The ambitious construction schedule will see the building completed by the end of January 2023, after which the building will remain on campus until 2030.

Learn more and get involved

“We are thrilled to be supporting the Third Quadrant Design team and their commitment to creating a healthier world through advancing regenerative building design, a cause that we are trying to address in our own developments,” says Ryan Thé, VP Development, Third Space Properties. “It’s because of young professionals like them that our industry will continue to evolve in the right direction and not only limit our buildings’ carbon footprint, but help sequester what the building industry has released in the past.”

Design and construction partners include:

- Dialog Architecture (architecture)

- RJC Engineers (structural)

- Integral Group (mechanical, electrical, passive design)

- RDH Building Science (energy and building envelope)

- Stantec (civil)

- I3 Building Science (geotechnical)

- Ledcor (construction manager).

The team is also seeking sponsors of cash and in-kind donations to help them cover the considerable costs associated with the construction project. Visit the Third Quadrant Design website to learn more and become a sponsor.